Welcome to the world of electric motors, where power and precision combine to drive industries forward. As a responsible equipment owner, you understand the significance of regular maintenance in keeping your operations running smoothly. But how often should you seek professional electric motor repair services from Ghaima Group to ensure seamless performance and longevity? In this article, we delve into the crucial factors that determine the ideal repair frequency. Let’s unravel the secrets behind preserving the heart of your machinery and unleashing its full potential.

Understanding the Importance of Regular Maintenance

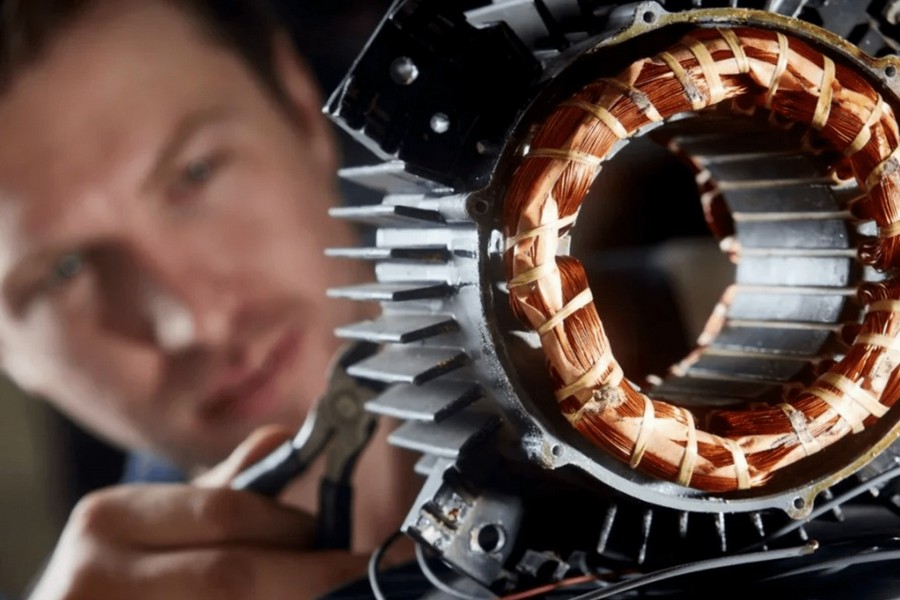

Proper maintenance is the cornerstone of maximizing the lifespan and efficiency of your electric motor. Neglecting regular upkeep can lead to decreased performance, unexpected breakdowns, and costly downtime. By adhering to a disciplined maintenance routine, you can identify potential issues before they escalate into major problems. An electro-mechanical company specializing in electric motor repair services can provide comprehensive inspections, cleaning, and necessary repairs. Their expertise ensures that your motor operates optimally, delivering the power and reliability your business depends on.

Factors Influencing Repair Frequency

The frequency at which you should seek electric motor repair services depends on various factors. The motor’s operating conditions, environment, workload, and maintenance history are vital in determining its repair needs. High-demand environments with heavy usage may require more frequent inspections and maintenance than motors operating under lighter loads. Additionally, harsh operating conditions, such as extreme temperatures or exposure to contaminants, can accelerate wear and necessitate more regular repairs. Collaborating with an electro-mechanical company experienced in diverse industries can provide valuable guidance tailored to your specific motor and operational requirements.

Benefits of Proactive Maintenance

Proactive maintenance, including regular electric motor repairs, offers numerous benefits that go beyond avoiding sudden breakdowns. Timely repairs prevent minor issues from escalating into significant failures, saving you from costly repairs or replacements. Proactive maintenance enhances your motor’s efficiency and performance, reducing energy consumption and optimizing productivity.

In Conclusion

In summary, the frequency of electric motor repairs depends on several factors specific to your operations. Regular maintenance and repairs conducted by a trusted electro-mechanical company are essential for preserving the reliability and efficiency of your motor. By investing in proactive maintenance, you not only minimize costly downtime but also extend the lifespan of your equipment. Stay ahead of potential issues, optimize performance, and reap the benefits of a well-maintained electric motor. Contact an experienced electro-mechanical company such as Ghaima Group today to ensure your engine operates at its full potential.

Hiking addict, traveler, band member, Vignelli fan and independent Art Director. Working at the sweet spot between design and mathematics to save the world from bad design. Nothing ventured, nothing gained.